One of the best investments in time and resources a grower can make is to improve the efficiency of their heating system. With the high price of fuel today, this will provide savings every hour the system operates. Savings of 2% - 10% are common.

Combustion efficiency

Efficiency testing of a furnace or boiler is a 10-minute procedure that can indicate when problems begin to occur. It is the key to saving money on the heating bill. Increasing efficiency a few percent can significantly reduce fuel consumption over the heating season. For example, a 2% increase in efficiency of a million Btu/hr burner operating 2,000 hours will save about 289 gallons of fuel oil, 367 ccf of natural gas or 432 gallons of propane. This is quite realistic based on efficiency tests conducted on greenhouse heating equipment in New England.

A first step toward this is to have a competent service person clean and adjust all furnaces and boilers before the start of the heating season. Service should include:

Oil fired units

Changing the fuel filter on oil furnaces. It is surprising how much sludge and dirt collects in the fuel. Tanks should be located away from dusty locations and watertight fittings should be used. Outdoor tanks should be protected from harsh winter weather with an enclosure.

Replace the nozzle and adjust the electrodes. Wear increases the nozzle orifice opening increasing fuel usage. Select a nozzle with the correct spray angle to fit the firebox. Check the fuel pump pressure. Follow the manufacturers’ recommendations.

Heat exchanger

Soot should be removed from heat exchanger surfaces. A 1/8-inch soot deposit can increase fuel consumption by as much as 10%. Brush and vacuum surfaces or clean them with special cleaning compounds.

Heat exchange surfaces, such as tubes, fins and radiators collect considerable dust and dirt in a greenhouse atmosphere. Brush and vacuum surfaces to increase heat output. Clean blowers for efficient air movement.

Drain off dirty water in steam and hot water systems. Analyze boiler water periodically to determine if treatment is needed.

Barometric damper

Excessive draft increases the heat loss when the heating unit is on the standby. A barometric damper (oil fired heating unit) or draft hood (gas fired units) should be located in the first 12 inches of the stack nearest the burner. Its purpose is to maintain a constant draft on the fire. Savings can be as much as 10%.

Make-up air

The recommendations to tighten up the greenhouse for the winter may adversely affect the operation of the furnace or boiler. This is usually due to the lack of oxygen for combustion. How much air is necessary for good combustion? With most gas burners adjusted to operate with 50% excess air, 20 cu ft/1,000 Btu of heater input is generally considered adequate. With fuel oil, 1,400 cu ft/ gallon of No. 2 fuel oil is required for proper combustion and venting. A motorized louver or 6-inch PVC pipe that provides make-up air near the burner is necessary. Make sure that the intake is located so that it is not blocked by snow.

Adequate voltage to the heating unit

Low voltage causes motors to burn out by overheating the windings. It can also affect the operation of the transformer creating a weak spark. Voltage at the heating unit should be at least 115 volts. Two causes of low voltage are inadequate power to the electric distribution panel in the greenhouse and too small a wire size that feeds the furnace. This problem is quite common in hoophouses where long wires are needed to power heaters that are located at opposite ends.

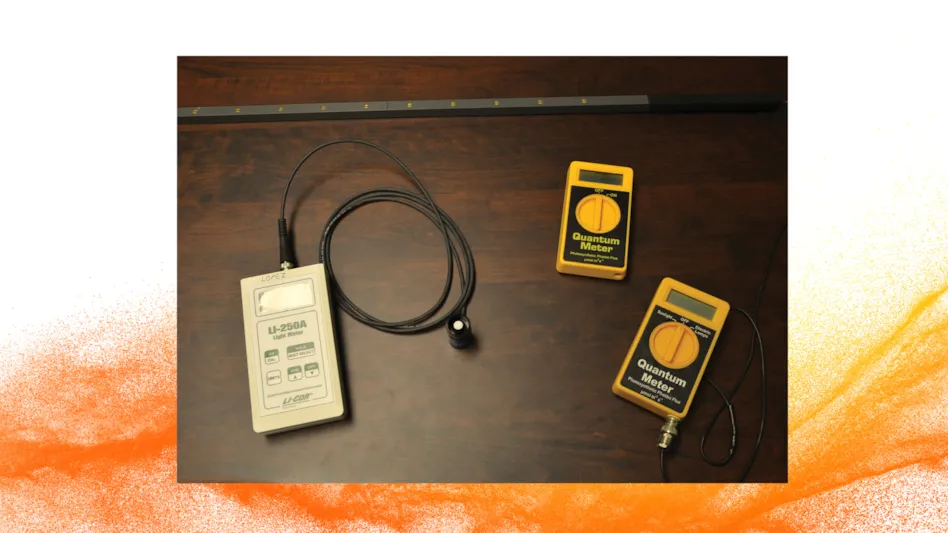

Environment control sensors

Thermostats and sensors should be cleaned several times a year. Blow off dust with compressed air. Check for accuracy by placing in an ice bath or comparing to an accurate digital thermometer. Be sure that the sun shield is in place and that the location is close to the plants. Aspiration of the sensors can reduce the differential between the high and low setting by several degrees.

Explore the December 2023 Issue

Check out more from this issue and find you next story to read.

Latest from Greenhouse Management

- Landmark Plastic celebrates 40 years

- CropLife applauds introduction of Miscellaneous Tariff Bill

- Greenhouse 101 starts June 3

- Proven Winners introduces more than 100 new varieties for 2025

- UF/IFAS researchers work to make beer hops a Florida crop

- CIOPORA appoints Micaela Filippo as vice secretary-general

- Passion grows progress

- Registration opens for Darwin Perennials Day