Greenhouse Management: What do growers need to know when they’re upgrading their lighting technologies to an LED system?

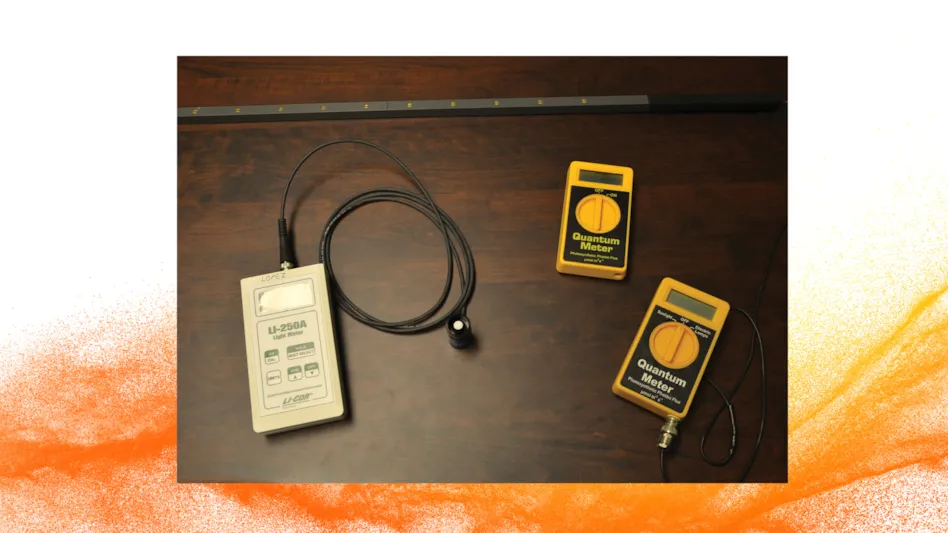

Abhay Thosar: Until now, growers were limited to HID lighting and, based on their current lighting infrastructure, they were limited to the micromoles/m2/sec (PPFD) that they could target for their crops because of the power intake as well as the heat discharged by the HIDs. With LED technology, growers can separate the light and heat and optimize the supplemental lighting as per their crop needs. The first and foremost thing for us is to understand the objectives of the grower for their crop, keeping in mind their infrastructure (light transmission) as well as their geographic location (natural lighting conditions). With LEDs, growers have options to optimize the supplemental lighting to maximize the production and quality of the crop. Each greenhouse is different and we offer a customized approach to the lighting requirements of the grower.

GM: What would you say to any grower who’s hesitant or on the fence about upgrading their lights?

AT: They need to understand that HPS technology is getting obsolete. In the next three to five years, they won’t be able to find the HPS bulbs because most of these companies are going towards a more sustainable environment and that’s why we are moving towards LEDs. So regardless of whether they like it or not, in the next three to five years, they will have to make the change.

There’s a fear of the unknown because they have been working with HPS for the past 20-25 years and now if they want to change over to LEDs, there’s the fear that they won’t be able to grow the crop exactly how they used to grow under HPS. So, in order to overcome that fear of unknown, we ask the growers to do trials in their greenhouse using LEDs. The growers can outfit one bay in the greenhouse or even one environment zone and compare the growth with their existing lighting. We offer horticulture support to the growers and we also offer the hand holding whereby we will work closely with the grower during the trial and learning.

GM: What’s a big question that growers tend to have?

AT: “What’s the best spectrum for my crop?” Growers ask this because there are different lighting companies coming up with different spectrums. The light quantity trumps the light quality. Focus on the crop lighting requirements, anticipating the objectives to achieve, infrastructure and geographic location. Efficacy of the LED lights in terms of micromoles/watt and the pricing in terms of dollars/micromole would be a good measure to compare. Apart from pricing, there are other technical considerations to investigate. Post-sales support and services (horticulture and technical) play important parts for the grower since there is a learning curve when working with the LEDs, so they should opt for companies that provide the services.

Explore the May 2023 Issue

Check out more from this issue and find you next story to read.

Latest from Greenhouse Management

- Landmark Plastic celebrates 40 years

- CropLife applauds introduction of Miscellaneous Tariff Bill

- Greenhouse 101 starts June 3

- Proven Winners introduces more than 100 new varieties for 2025

- UF/IFAS researchers work to make beer hops a Florida crop

- CIOPORA appoints Micaela Filippo as vice secretary-general

- Passion grows progress

- Registration opens for Darwin Perennials Day