After eight years of service in the Marine Corps, Ariel Montanez wasn’t really considering a career in horticulture. “The only thing I knew about plants was how to use them as camouflage,” says Montanez, who served in Okinawa and other deployments around the world before finishing his service at Camp Lejeune in North Carolina. “I never even thought of plants as a business."

But after earning his business degree, Montanez landed his first post-military job at Monrovia Nursery in 2006 as a human resource assistant.

He worked his way through roles in shipping and logistics, purchasing and maintenance before Monrovia closed its North Carolina facility. At that point, Montanez interviewed for a similar shipping role at Pender Nursery in Garner, North Carolina — but they offered him the position of general manager instead.

“I told them, ‘Look, you realize I don’t have a horticulture background. I don’t know plants,’” Montanez says. “But what I did understand was how to set processes and how to organize people.”

Even without classic plant knowledge, Montanez’s military background provided the right mix of skills to lead the growing team at Pender Nursery, where he’s been since 2013.

“That’s probably the one thing that has helped me as general manager, my military experience: how to organize people, how to motivate people, how to find and develop talent,” Montanez says. “The leaders I had in the military challenged me to be better and work harder, and that’s something I bring to this role. I enjoy seeing people grow and develop.”

Troop mentality

Although Montanez learned leadership from the Marine Corps, he’s definitely “not a drill instructor style” manager.

“I think the drill instructor style works for building Marines, but not necessarily for leading employees. You get more out of people by motivating them,” he says. “I’ve worked for people who had an authoritative leadership style, and honestly, I didn’t enjoy that. I’d rather work for somebody who valued my opinions.”

Instead, Montanez works hard to foster a team environment where everyone has a voice. “From the beginning, I wanted to instill a culture of respect, where people feel that their ideas matter and they’re taken seriously,” he says.

To that end, Montanez meets with the growing, potting and propagation teams weekly to make sure everyone stays on the same page. They discuss plant issues first, then people and processes second – but he’s careful to keep meetings on point.

“If we get into a subject that needs more planning and thought, we’ll table it and (reassign it to) the right team leaders so we’re not dragging it out,” he says. “A lot of people dread meetings because they get stuck in meetings that don’t pertain to them, so I try to make sure that our meetings are meaningful.”

When he stepped into the GM role, Montanez faced a steep learning curve juggling plant production cycles for hundreds of SKUs in Pender’s diverse inventory. The wholesale nursery, which was the first licensed grower of Encore Azaleas on the East Coast, also grows perennials, groundcovers, shrubs, trees and grasses on about 40 acres (10 of which are covered).

_fmt.png)

“If you don’t manage your inventory, you’ll never be able to manage your sales,” he says, “so I spend a lot of time looking at our crops to see what’s moving. I’m strict about inventory management because of the effect it has on the bottom line.”

To keep products moving through Pender Nursery at a profit, Montanez closely assessed all the processes involved in the operation, and then identified opportunities to improve efficiency. One of the biggest changes happened on the potting line.

“When I first took over, the potting team consisted of 17 people, and the machine we were using wasn’t very efficient,” he says. “By sitting down and looking at how our nursery is arranged, asking ourselves some questions, and experimenting with different processes, we were able to reduce that headcount down to eight people. We ended up eliminating the machine; we’re getting more done without it, and we’re really happy with the quality of the potting.”

Through continuous improvement and strict inventory management, Montanez streamlined the nursery’s operation to alleviate ongoing labor challenges. “When I took over in 2013, we had 60 to 65 people, and just through analyzing processes, we’ve been able to dwindle that down to 40 people at peak,” he says. “We’ve been able to really impact our labor costs and our bottom line.”

To help Pender Nursery improve its plant quality, and ultimately, maintain profitability, Montanez continues to innovate more efficient solutions.

“Be flexible and be prepared for change, because change is always going to happen,” he advises other growers. “If you fear change, that’s the nail in the coffin for a lot of businesses. Don’t be afraid to make mistakes and learn from them so you can become better.”

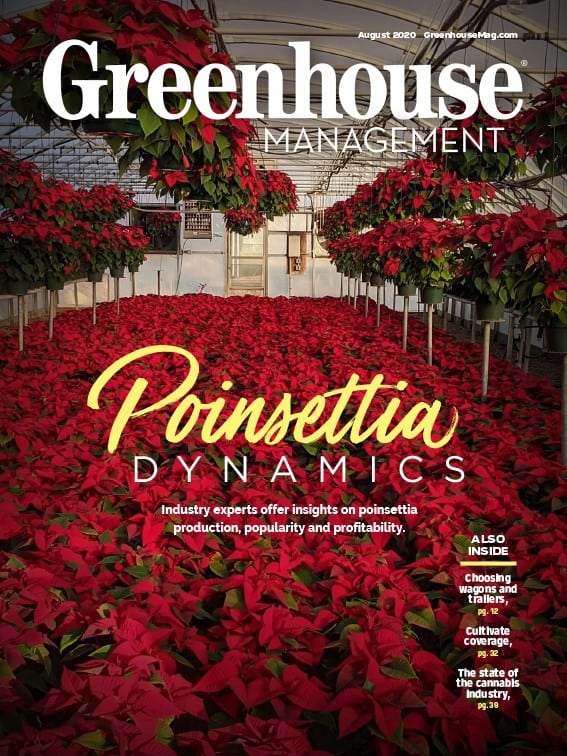

Explore the August 2020 Issue

Check out more from this issue and find you next story to read.

Latest from Greenhouse Management

- Passion grows progress

- Registration opens for Darwin Perennials Day

- U.S. Department of Labor finalizes farmworker protection rule

- Azo Root is now available from Harrell’s

- Bidens ferulifolia Blazing Glory

- Rob Hanifin joins Ridder North America as product specialist for climate screens

- The importance of measuring light

- Spigelia marilandica