Growers can use a range of control strategies to reduce temperatures and humidity levels, including increasing air exchange (ventilation), reducing incoming radiation (glazing materials and shading), using air conditioning (evaporative cooling) and producing plants that are tolerant of higher temperatures. It is important to properly service the equipment used to maintain optimum growing conditions inside your greenhouse during the warmer part of the year.

Maintaining equipment

Mechanically ventilated greenhouses require louvered inlet openings, exhaust fans, controls and electricity to operate the fans. In a naturally ventilated greenhouse, the same maintenance issues apply, except for the use of exhaust fans.

Louvered inlet openings are often controlled by an electric motor or other type of actuator attached to a chain or push rod. Window-type openings are often adjusted using a rack-and-pinion system operated by a motor attached to a low-speed gear box. The motors and other types of actuators, gear boxes and rack-and-pinion systems require periodic lubrication. Consult the owner’s manual or contact the manufacturer to make sure the correct type of lubricant is used. In some cases, adjustments of limit switches (e.g., to stop the motor/actuator when the ventilation window is fully opened or closed) need to be made.

While checking system components, it is recommended to also check the overall performance. The openings should perform as intended (e.g., they open and close completely, all components align properly).

Ventilation fans can be direct-driven, gear-driven or belt-driven, indicating how the electric motor is attached to the fan blades. These motors can be single-speed, multiple-speed or variable-speed, each type increasing the level of performance.

Servicing fan motors is typically done by a licensed technician. Other adjustments, including making sure the drive belt is not worn and is properly aligned and has enough tension, cleaning and checking the alignment of fan blades and checking the proper installation of protective guards, are often done by growers and can significantly improve the operation and safety of the ventilation fans.

While an electrician is on hand to check the fan motors, consider having him do an inspection of the entire electrical system. Conducting periodic inspections can reveal electrical code issues that need to be addressed as well as reduce the risk of electrical shortages that may cause work interruptions or worse, may result in personal and/or property damages.

Checking and adjusting control systems can be as simple as adjusting the setting on a thermostat or much more complicated in the case of a computer-control system. Computer-control systems typically include both high (115 volts of alternating current and higher) and low voltage (typically less than 24 volts) components and wiring. System adjustments can be made through the software that allows for user interaction. However, it is recommended that servicing the electrical parts of the control system be done by a service technician or a knowledgeable electrician.

Ventilation operation

Greenhouse ventilation systems are designed to provide sufficient air exchange and appropriate air distribution throughout the structure. Exhaust fans determine the air-exchange rate, while air distribution is most influenced by the ventilation inlets. In some greenhouses, additional circulation fans provide air distribution by moving air within the greenhouse, but without providing any exchange with the outside air.

In a tight greenhouse, exhaust fans create a small vacuum (negative pressure) that causes air to enter the greenhouse through the ventilation inlets. This vacuum is called the static pressure difference and links the fan and inlet performance. There are three primary features to check when evaluating a mechanical ventilation system:

1. Static pressure difference.

2. Fan capacity.

3. Effectiveness of the inlet opening.

Static pressure

Static pressure difference is the driving force for air movement in a ventilation system. Air moves from areas with a higher static pressure to areas with a lower static pressure. Air enters or leaves a greenhouse because the interior static pressure differs from the outside.

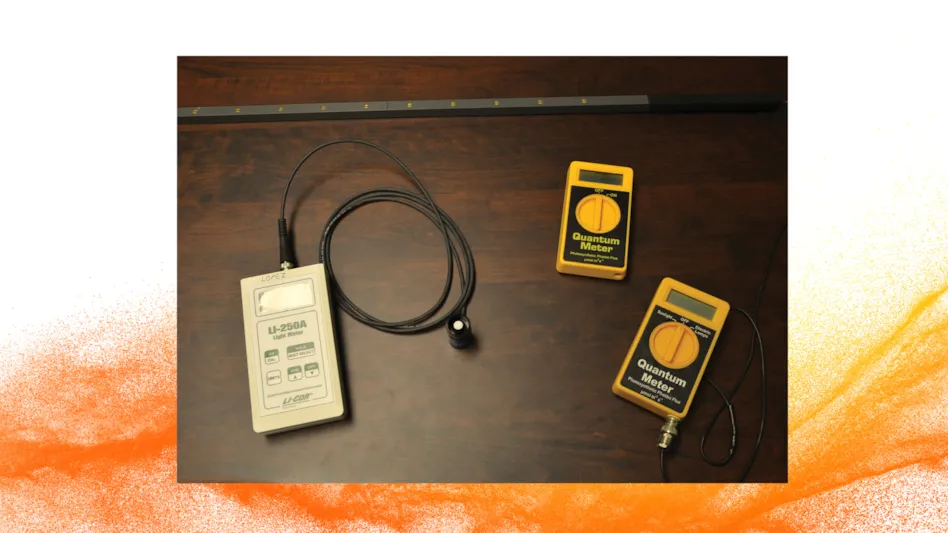

Static pressure differences can be measured with a manometer that indicates pressure changes displayed by a colored fluid level. In greenhouses, the static pressure difference between the ventilated space and outside is measured in inches of water. By maintaining a relatively constant static pressure difference between the inside and outside air, the speed of the air entering through the ventilation inlet will also be relatively constant. This inlet speed is important to ensure proper mixing of the incoming outside air with the greenhouse air.

In mechanically ventilated systems, the static pressure difference should be maintained at approximately 0.05 inches of water with an acceptable operating range of 0.03 to 0.13 inches. Interestingly, few greenhouses monitor the static pressure difference.

Care must be taken in positioning the tubes connected to the manometer measuring ports. Be sure they are not exposed to moving air, which would result in the measurement of “velocity” pressure. A manometer should be permanently installed to provide an indication of the static pressure difference. This can be accomplished using an inexpensive inclined manometer or a manometer with an electronic control capacity for inlet opening positioning.

Ventilation fans

Greenhouse ventilation fans are typically selected for their operating performance at 0.10 to 0.125 inches of water pressure to account for exhaust fan design and inlet restrictions. Even higher operating performances are desirable when insect screening is installed, especially when screens with small opening sizes are used. Dirty fan blades can significantly reduce the efficiency of exhaust fans.

Fan capacity (cubic feet per minute) is determined by multiplying the average exhaust air speed (feet per minute) by the area of the fan face (square feet). The average exhaust air speed can be determined using a vane anemometer. A representative number of readings are taken across the outlet opening as close to the outlet as safely possible. These numbers are averaged to determine the average exhaust air speed.

Another way to determine fan capacity is by measuring the fan blade rotational speed in revolutions per minute (rpm). The amount of air a fan moves is directly proportional to its rotational speed.

Fan blade rpm and rated airflow capacity are often listed on the housing nameplate or can be obtained from the manufacturer. For belt-driven fans, motor rotational speed will typically not equal blade rpm.

Fan rpm can quickly indicate if belts are loose or worn or if the supply voltage is too low. Inadequate wiring can lead to substantial voltage drops, causing fans to run at a lower rpm.

Fan rotational speeds can also be measured using a strobe light or tachometer. Tachometers that are pressed against the center of the fan shaft should be used carefully so that no personal or equipment damage occurs if the tachometer shaft slips off the fan shaft.

The effectiveness of the inlet opening is characterized by the inlet air speed that should be quite high, 700 to 1,000 feet per minute (fpm), to ensure proper mixing with the greenhouse air. Air speeds across inlet openings are not uniform. The air speed will be zero at the edges of the inlet and typically increases to its maximum near the middle of the inlet opening. A small-head vane anemometer or a hot-wire anemometer can be used to measure air speed across the opening of the inlet to determine the maximum air speed reading.

- A.J. Both

{sidebar id=1}

A.J. Both is associate extension specialist, Rutgers, the State University of New Jersey, Bioresource Engineering, Department of Plant Biology and Pathology, (732) 932-9534; both@aesop.rutgers.edu.

April 2008

Latest from Greenhouse Management

- Landmark Plastic celebrates 40 years

- CropLife applauds introduction of Miscellaneous Tariff Bill

- Greenhouse 101 starts June 3

- Proven Winners introduces more than 100 new varieties for 2025

- UF/IFAS researchers work to make beer hops a Florida crop

- CIOPORA appoints Micaela Filippo as vice secretary-general

- Passion grows progress

- Registration opens for Darwin Perennials Day