Torrington, Connecticut, is home to a CEA growing operation that not only feeds the community but provides opportunities for those in need.

CT Food 4 Thought is a nonprofit organization with a mission to “provide healthy and locally grown food to the community while creating job opportunities for local residents.” They do that by leveraging two 15,000-square-foot, three-peak Atlas greenhouses that support a combined 30,000 square feet of NFT hydroponic growing area, producing 12,000 heads of lettuce per week.

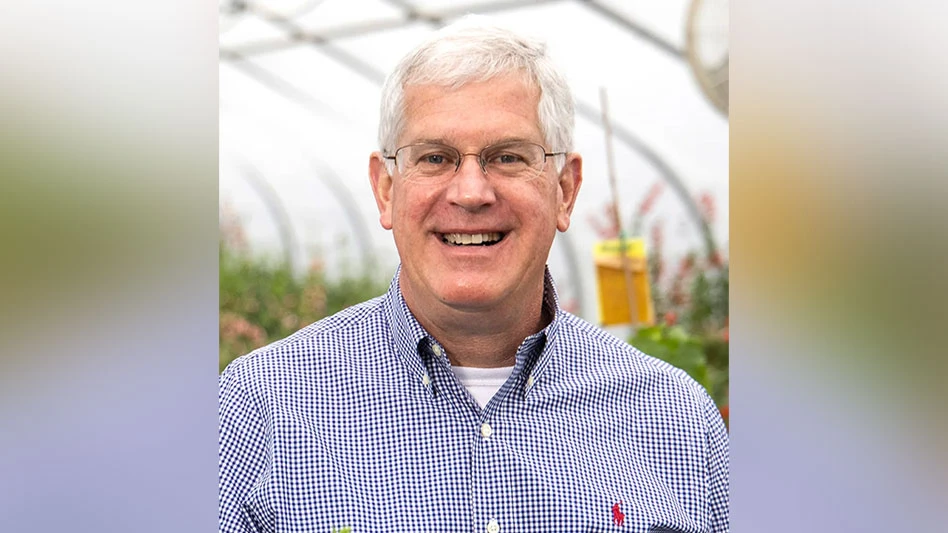

Adviser-cum-business manager Jon Jensen and general manager Brandon Schroen have been working on the operation since 2021. And not only does it provide a living wage and job training for employees, CT Food 4 Thought also provides produce to local grocery stores, schools, hospitals and food security programs.

“It’s like Disney World,” Jensen gleefully says of the greenhouse. “Nobody believes me.”

On the way to its current level of production, CT Food 4 Thought started growing its leafy greens under natural light conditions with some supplemental help from high-pressure sodium (HPS) lighting that covered just about 20% of the growing area. But the early lighting system was not as efficient as it needed to be and didn’t cover enough area, much less provide the lighting necessary to produce the capacity and quality of greens the organization was aiming for.

And so, early in 2025, CT Food 4 Thought transitioned to Hydrofarm PHOTOBIO LEDs. It was a game changer, according to Jensen.

“Number one, we get optimal, steady quality and growth,” Jensen says. He points out that the ability of CT Food 4 Thought to offer a steady supply and consistent quality is crucial for marketing its produce to buyers in schools and grocery stores. “If you’re a traditional farm, you can’t do that.”

Schroen notes that Hydrofarm and the PHOTOBIO team have been incredibly helpful in getting the 310 PHOTOBIO 330-watt LED bars online. And during the build-out phase, as lights come online, Schroen has had time to trial and tweak his NFT solution so that the greens get the right nutrient mix for the new light they will be receiving.

“We have our nutrients pretty well dialed in. We just need to pair it with the lights correctly. And we’ve seemed to dial that in over the last couple of weeks,” he says.

Currently, Schroen is using a timer for the lights. But one of the biggest selling points of the PHOTOBIO system is that it will work with any commercial-grade greenhouse controllers, which is the brain of the operation. He’ll soon be able to run the lights based on daily light integral, which will be far more accurate and efficient.

“The controller operates everything in our greenhouse: the shade curtains, the positive pressure, the cooling, the heating,” he says. “And this is just the next feature that we can build into it.”

Both Jensen and Schroen are impressed with the lights’ efficiency. They report that the PHOTOBIO system can run on the same outlet as the HPS lights but only use half of the energy of the previous system while lighting significantly more area.

For Jensen, the key to the success of PHOTOBIO lights and CT Food 4 Thought comes down to one word: “consistency.”

More from the 2025 Lighting Market Report:

From the Sponsor: Growing together

DLI: Measuring daily light integral for greenhouse production

Explore the August 2025 Issue

Check out more from this issue and find your next story to read.

Latest from Greenhouse Management

- Stay warm, stay ready

- Coleus Lime Edge (Skeletal) named 2025-26 Flower of the Year in Japan

- New SustainaGuides on lighting and water conservation from Sustainabloom available

- Chad Miller shares best-performing plant varieties in Colorado State University trial gardens

- Meet the All-America Selections AAS winners for 2026

- Source.ag raises $17.5M for applied AI in CEA, pushing total funding past $60M

- How to grow a rainbow

- Cultivating responsibility: Why labor practices matter in greenhouse operations