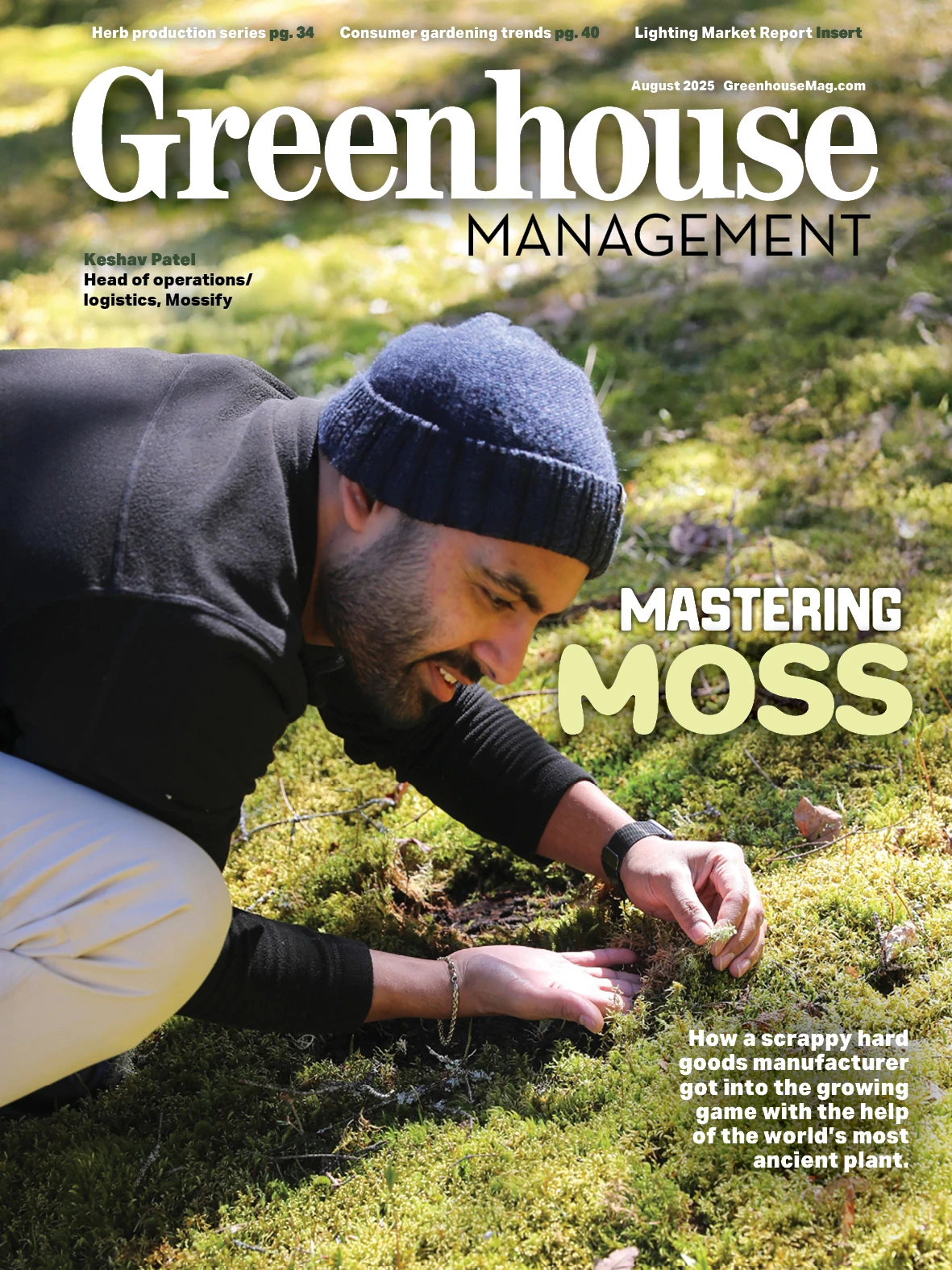

Editor's Note: This article originally appeared in the August 2025 print edition of Greenhouse Management under the headline “Mastering moss.”

On the eastern shores of Lake Nipissing in the Ontario bush, there is a 15-acre plot of land where the boughs of the white pine, ash and aspen typical to the Great Lakes-St. Lawrence forest region whisper in the wind.

Below the spreading branches of the forest canopy, thriving in the unique transitional ecosystem between boreal forest to the north and hardwood forest to the south, is an astounding array of bryophyte species — mosses in dazzling shades of green, each structurally and visually unique from each other. They spread across the forest floor, cling to rocks and creep up trunks.

Often wandering these green environs, not without purpose, is the 28-year-old president and founder of Mossify, Lucas Picciolo. This verdant, rugged and idyllic acreage is his company’s newly launched business venture: a farm for the propagation, cultivation and harvesting of moss.

It’s far from any major population center, but it’s even further from the spooky wildness of a 2019 Toronto Halloween night that saw Picciolo shunning revelry in search of a business idea. How could he have known then that in just six years, he would find himself wrestling with a skid steer, building a single-span greenhouse and shipping loads of sustainably harvested moss from the Canadian bush to greenhouse growers, consumers and garden centers throughout North America?

'Wood blocks with moss in them'

At 22 years old, Picciolo was working in food service and construction. But his entrepreneurial spirit chafed at his wage-earning reality. And on that fateful Halloween night, he decided to turn down invitations for a night out in favor of business ideation.

“A lot of my friends were going out and going to Halloween parties, and I really wanted to go out, too, but I think I wanted something different,” he says. “I wanted to change, and I wanted to think deeper.”

He put everything aside and dove deep into research. He found himself thinking about wasted wood at construction sites, something he noticed home builders had to pay to get removed. He wanted to make use of the wood.

One day, as the story goes, Picciolo noticed a bit of moss on a board. Inspiration struck. He picked up a scrap block, carved out the word “create” and filled it with moss. Struck by the aesthetic of his creation, he brought it inside as décor and found that visitors to his home wanted one of their own. So, Picciolo started building.

“We would get the wood, clean it up, cut it to size and then we would carve out different images, logos, names and put moss inside of it,” Picciolo says. “And that’s how the company kind of just started — selling wood blocks with moss in them.”

In May 2020, as the world stopped because of the COVID-19 pandemic, Mossify was born in Picciolo’s garage in the Toronto suburbs, with online sales of moss art and merch. A pandemic obsession with bonsai found him wanting to shape his houseplants like the diminutive Japanese trees. His second product, the bendable moss pole, was born.

As the garden industry boomed during the pandemic, so did Mossify sales. The company moved into a warehouse in 2022 and grew its houseplant accessory line, as well as its staff, including Aidan Endre, current head of growth; Keshav Patel, head of operations and logistics; and Thiago Jaques, head of media.

But five years into the Mossify journey, Picciolo says there was friction with the live moss supply.

“We would place orders, and the volumes would get larger, and we would obviously negotiate a more aggressive price. But if we placed an order in May of 2024, we would get the product seven months later. That would really affect everything.”

That delay, along with how much they were spending with their moss vendors, caused the Mossify team to look closely at the books. And while they weren’t farmers or agronomists or biologists or horticulturists, they realized that investing the money they were spending with vendors on growing their own moss supply could solve some problems.

For one, a property for moss growing would add value to the company. But also, they would have greater transparency and control over the ecological impact and quality of the moss while also decreasing supply chain issues.

“To be completely honest, we wanted a new challenge,” Picciolo says. “We were kind of just doing the same thing day after day, and … we’re a very competitive bunch.”

From manufacturers to greenhouse growers

While the Canadian bush is bustling with moss, building a moss farm along the shores of Ontario’s third-largest lake is not an easy undertaking. Picciolo says starting the farm was like starting a whole new business. His garden industry manufacturing business was becoming a propagation, farming and greenhouse growing business.

The investment cost required “a lot of zeros,” Picciolo jokes.

While moss grows naturally on the 15 acres of forested and rocky land, a farm still needs constructed spaces to manage, collect and move the harvested moss inventory. Despite huge initial optimism about infrastructure installation on the remote site, Picciolo admits the challenges began on day one of owning the property.

“We had a skid steer delivered the first day to rip up some ground and start getting to work, installing some soil and stone,” he says. “The ground was a lot more wet than we thought. The skid steer broke down twice and got stuck, so I had to call a tow truck to get it out, and that was all within the first three days.”

Since then, Picciolo has been going up to the farm almost every week to work, and his team and dad help out as well. They now have space to manage the harvest, but Mossify will also be moving production under cover.

Recently, the team built a 25-foot-tall, single-span greenhouse, where they will focus on controlled environment moss productions for five to 10 species of moss they will pick from the over 30 species that grow on the property. Currently, they are in the research phase and working to understand what type of under-cover environment they need to cultivate to accelerate the moss growth.

“I didn’t go to college. I don’t have a horticulture degree, but we know a lot of people that do,” Picciolo says. “I really enjoy solving problems, but some problems are really tough to solve. We’ll definitely do some testing. We’ll definitely have to gauge light and humidity.”

The advantage of having started as a supplier for greenhouse growers is that Mossify can leverage the good relationships they’ve built to improve their knowledge of cultivation. Picciolo notes the industry’s willingness to share information has been incredibly beneficial.

“It’s the relationships that we’ve built over the years with extremely reputable growers, farmers and retailers that are multi-generational. They have guided us as well and given us advice. You pick up the phone; you send them a quick text. You know, it’s not too big of an industry, and people help each other.”

But more than just growing, Mossify has had to learn important lessons in logistics that growers of live plant material have always struggled with.

“Now with the moss farm, we’re dealing with a completely different product,” Endre says. “We are working with live moss and learning how to store it, learning how to ship it and learning how to package it so that in the end, it can be a beautiful product for the customers."

Capitalizing on consumer gardening trends

Katie Dubow, president of Garden Media Group, which releases the annual Garden Trends Report, says Mossify has likely been successful because of how they run their company: with ecological values and an eye for products that spark consumer interest.

Dubow notes that moss is thriving outside of forests as part of a larger trend for landscapes that look established. It’s part of the “lived-in gardens” trend, with gardeners using plants like moss to add a feeling of serenity and comfort to their homes and outdoor spaces.

“The idea of moss as this, like, ancient plant, and the way that it’s so tiny — it is a fascinating plant in itself,” says Dubow, pointing out a moss backdrop behind her during a video interview. “And I think that the calmness of it helps because we’re in this wellness movement. And it can be adopted to interiors, exteriors. I think it’s definitely having a moment.”

One of those mossy moments came from the highly influential RHS Chelsea Flower Show 2025 in England. There, garden designer Zoe Claymore worked with The Wildlife Trusts to build the “British Rainforest Garden,” which made moss a star rather than a background character. The garden featured a fern and moss wall meant to evoke the ancient quality of a British rainforest and won the People’s Choice Award for Best All About Plants Garden, a show category focusing on unusual and specialist plants.

Moss was also featured prominently in legendary Japanese garden designer Kazuyuki Ishihara’s Cha No Niwa Japanese Tea Garden, which won RHS Chelsea Garden of the Year and the People’s Choice Award for Best Show Garden at Chelsea. Key to tranquility, softness and artfulness of the garden was a layered palette of mosses that covered stones, which made the installation look as if it had been there for hundreds of years.

Packaging designed for dormant plants

Jaques designed the farmed-moss product packaging. It’s two pieces: a tray to hold the moss, and a sealed paper bag with a window to see the product inside. He explains he wanted to make it easy for the customer to understand what the product does, how it’s different from other moss and how to revitalize it, as it ships in a dormant state, all while keeping the design minimal. To do so, he used just three colors and took cues from traditional greenhouse and IGC plant tags.

Picciolo created the tray inside the package with a 3D printer. Much like the pots used to grow and ship plants in greenhouses, the tray is designed so the moss can grow inside of it, even in the bag and after shipping, and be reused.

While creating the product and its presentation, Picciolo says the team took a lot of lessons from the hard goods space they were previously in. Patel says he feels attention to detail was a big one.

“The background of knowledge that we had with the retail space, with the hard goods, definitely came into play with this one,” he says.

Understanding moss as a plant and product

Moss has a wide range of uses and can be placed in terrariums and vivariums, which house and maintain living organisms. It can also be used as a top dressing for plants, as an addition to bonsai trees or for landscaping projects, living walls and green roofs.

Picciolo says when comparing a square acre of trees and a square acre of moss, moss filters more carbon dioxide. It’s also one of the oldest plant groups on earth, and it’ll be here long after we’re gone.

“A lot of people that I’ve talked to recently after we bought the farm keep saying to me, ‘Why are you selling moss? If I see moss on the driveway, I’m killing it, or I’m taking it out,’” Patel says. “But it can help your plants. It can help your greenscape thrive. Just educating everybody is going to be something that I’m looking forward to.”

Picciolo says he hopes to develop new technology to help the environment with moss, like bogs and peatlands.

“If we can help a contaminated site and bring it back to life with moss, I think we’d be very excited about that,” he says.

A rolling stone still gathering moss

The old adage says that a rolling stone gathers no moss, but despite Mossify’s movement, it continues to collect and study the many species of bryophyte available on its acreage, a great deal of which the team has yet to really study and understand.

Currently, the company is selling direct to consumers and wholesale, taking pre-orders and getting ready to build inventory for show and distribution season.

“We’re in it for the long haul,” Picciolo says. “We’re really in it to change the industry, as we’ve done in the past, and continue to grow and thrive and beyond, involve local government programs or local community, just keep it as prosperous as possible.”

He says he prides himself and his team on how scrappy they’ve been while growing Mossify, and he recommends other growers consider taking more risks, too.

“I think those people that are making the decisions on a computer have to get out there, get busy and think about new things that they can do,” he says. “That’s where my passion came from: developing things. These executives at large greenhouses — I hope they’re getting dirt under their fingernails still.”

Explore the August 2025 Issue

Check out more from this issue and find your next story to read.

Latest from Greenhouse Management

- The resolute

- Stay warm, stay ready

- Coleus Lime Edge (Skeletal) named 2025-26 Flower of the Year in Japan

- New SustainaGuides on lighting and water conservation from Sustainabloom available

- Chad Miller shares best-performing plant varieties in Colorado State University trial gardens

- Meet the All-America Selections AAS winners for 2026

- Source.ag raises $17.5M for applied AI in CEA, pushing total funding past $60M

- How to grow a rainbow