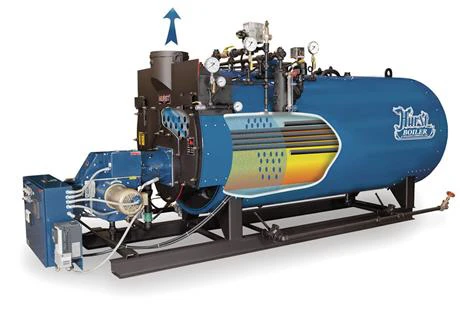

The Hurst internal stack economizer is a factory-optional device that is designed to increase the operating efficiency of a boiler, cutting down on its operational costs over the lifetime of the boiler. By integrating the stack economizer directly into the boiler, it acts as a waste heat recovery device, ensuring that this available heat does not go unused. Instead, the heat is recovered to essentially preheat the boiler’s makeup water.

Using an economizer does not just prevent heat loss — it can also extend the life of the boiler. Stresses from using cooler temperature make-up water can subject wear and tear on the boiler’s structural integrity over time. This shock effect occurs as the boiler’s fixed tube-sheets and fire-tubes rapidly contract from the sudden make-up of cooler temperature water. However, when this water is pre-heated, the temperature differential is far less extreme, putting less strain on the boiler and giving it a longer operating life.

To learn more, visit the Hurst Boiler website.